In recent years, the art of barbecuing has evolved from a simple backyard pastime to a sophisticated culinary experience. With the rise in popularity of grilling and smoking, barbecue enthusiasts are constantly seeking ways to elevate their outdoor cooking game. One key element in achieving the perfect barbecue is the type of fuel used, and charcoal briquettes have become the go-to choice for many grill masters. To meet the growing demand for high-quality charcoal briquettes, manufacturers have developed advanced machines that are designed to produce premium charcoal briquettes efficiently and effectively.

Enhancing Efficiency with State-of-the-Art Technology

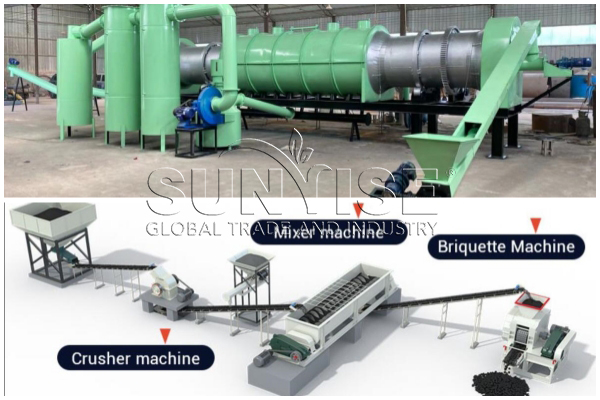

One of the key features of modern barbecue charcoal briquette making machines is their use of state-of-the-art technology to enhance efficiency and productivity. These machines are equipped with advanced mechanisms that allow for the quick and efficient production of charcoal briquettes. The process begins with the feeding of raw materials such as charcoal dust, sawdust, or wood chips into the machine, where they are compressed and extruded into uniform-shaped briquettes. The machines are designed to operate at high speeds, ensuring a continuous output of charcoal briquettes that meet the highest standards of quality and consistency.

Ensuring Quality and Consistency in Charcoal Briquette Production

Quality and consistency are crucial factors in the production of barbecue charcoal briquettes, as they directly impact the performance and flavor of the final product. Charcoal briquette making machines are equipped with precision control systems that monitor and regulate various parameters such as pressure, temperature, and moisture content during the production process. This ensures that the charcoal briquettes are of uniform size, shape, and density, resulting in a more consistent burn and heat output. Manufacturers can also customize the machines to produce charcoal briquettes of different shapes and sizes to meet the specific requirements of their customers.

The Environmental Benefits of Charcoal Briquette Making Machines

In addition to their efficiency and quality, charcoal briquette making machines also offer environmental benefits that make them a sustainable choice for barbecue enthusiasts. By using recycled materials such as charcoal dust or wood waste as raw materials, these machines help reduce waste and minimize the environmental impact of charcoal production. Furthermore, the use of charcoal briquettes as a fuel source results in lower emissions of pollutants compared to traditional charcoal, making them a more eco-friendly option for outdoor cooking. This aligns with the growing trend of consumers seeking sustainable and environmentally-friendly products for their cooking needs.

In conclusion, the barbecue charcoal briquette making machine represents a significant advancement in outdoor cooking technology, providing grill masters with a reliable and efficient tool for producing high-quality charcoal briquettes. With their state-of-the-art technology, precision control systems, and environmental benefits, these machines are revolutionizing the way charcoal briquettes are made, setting a new standard for quality and consistency in outdoor cooking. Embrace the future of barbecuing with a charcoal briquette making machine and elevate your grilling experience to new heights. Learn more about barbecue charcoal production line: https://www.sunrisecharpro.com/product/barbecue-briquette-making-machine-line/

Leave a Reply