Introduction to Biochar Briquettes

Biochar briquettes are a sustainable and eco-friendly fuel source derived from biomass, offering numerous environmental benefits, including carbon sequestration, soil enhancement, and waste reduction. Producing biochar briquettes at a rate of 10 tons per hour is a complex process that involves several stages, each requiring careful attention and specialized equipment. This passage will outline the key steps involved in the production process, highlighting the importance of each stage in creating high-quality biochar briquettes.

Feedstock Selection and Preparation

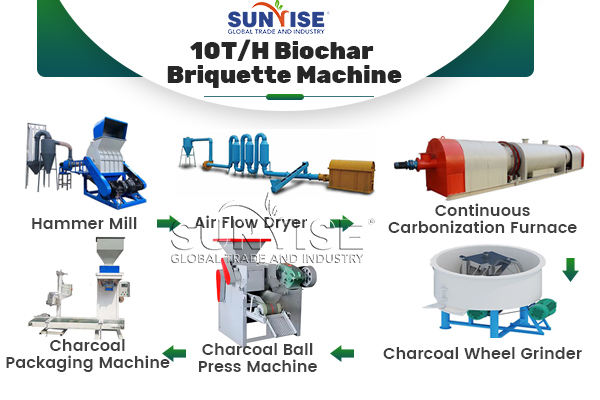

The production of biochar briquettes begins with the selection and preparation of suitable biomass feedstock. Common feedstock includes agricultural residues, forestry waste, and other organic materials rich in carbon. The choice of feedstock impacts the quality of the resulting biochar. Once selected, the biomass is subjected to size reduction using chippers and grinders to achieve uniform particle sizes, which is crucial for efficient pyrolysis and briquette formation.

Pyrolysis Process

The core of biochar production lies in the pyrolysis process, which involves the thermal decomposition of biomass in the absence of oxygen. This process occurs in a pyrolysis reactor or kiln, where temperatures typically range between 300°C to 700°C. At this stage, the biomass breaks down into solid biochar, along with volatile gases and tar. The pyrolysis conditions, such as temperature and residence time, are carefully controlled to maximize biochar yield and quality.

Cooling and Collection

After pyrolysis, the hot biochar must be cooled down before handling. This is usually achieved using a cooling system that ensures rapid temperature reduction while preventing oxidation of the biochar. The cooled biochar is then collected and screened to remove any oversized particles or impurities, ensuring consistency in the final product.

Batching and Mixing

For briquette production, the biochar needs to be mixed with binding agents to ensure cohesiveness and durability. Binders such as starch, molasses, or clay are commonly used. In the batching and mixing stage, precise proportions of biochar, binder, and any additives are combined in a mixer to form a homogeneous blend. This mixture is crucial for producing briquettes with the desired mechanical properties and combustion characteristics.

Briquetting Process

The briquetting process involves compressing the biochar mixture into uniform shapes using a briquette press or extruder. The press applies high pressure to form dense, compact briquettes that hold together during handling and combustion. The shape and size of the briquettes can be customized based on end-user requirements and application needs.

Drying and Packaging

Once formed, the biochar briquettes require drying to reduce moisture content, enhancing their combustion efficiency and storage stability. Drying can be achieved through natural air drying or mechanical dryers, depending on the production scale and environmental conditions. Finally, the dried briquettes are packaged for distribution, ensuring they are protected from moisture and physical damage during storage and transport.

Conclusion

The production of 10 tons per hour of biochar briquettes is a multifaceted process involving feedstock preparation, pyrolysis, cooling, mixing, briquetting, and drying. Each stage plays a critical role in ensuring the quality and sustainability of the final product. As demand for renewable energy sources grows, biochar briquettes offer a promising solution for meeting both energy and environmental goals. Visiting:https://www.char-molder.com/product/10-tph-biochar-briquette-making-machine-proposal/

Leave a Reply